For too long, current drying technologies with their

Massive infrastructure costs

Large footprint

Feedstock restrictions limiting current industrial dryer’s capability

have stood in the way of fully valorising what farmers and primary agricultural processors work so hard to produce.

The result?

Substantial resources wasted that could have been transformed to abundant food ingredients

High environmental costs where there could have been sustainability

Higher food and ingredient costs where there could have been affordability

Imagine a World Where

Farmers can dry all their fruits and vegetables into high value vibrant, premium quality shelf-stable powders for food and nutraceutical industry, reducing waste and delivering high value to the farmers

Abattoirs can dry their low-value organs into nutrient rich high value nutraceutical ingredients

Developing nations with poor infrastructure are able to preserve the output of their harvest at their peak thus reducing food waste and building food security

All this…. at a fraction of the cost and footprint of current drying technologies!

Carrot Powder

Mammalian organ powder

Brewers Spent Grain Flour

Introducing the PX20 Multipurpose Dryer

– Transformative Solution

Not just a dryer.

Not just a piece of equipment.

This is the solution and the future to ensuring sustainability, affordability and maximal valorisation of the world’s food resources!

The PX20 MPD is the World’s First Drying Platform designed to dry both liquids and solids separately & simultaneously to powders, in a single system, at a fraction of the cost and footprint of current industrial dryers.

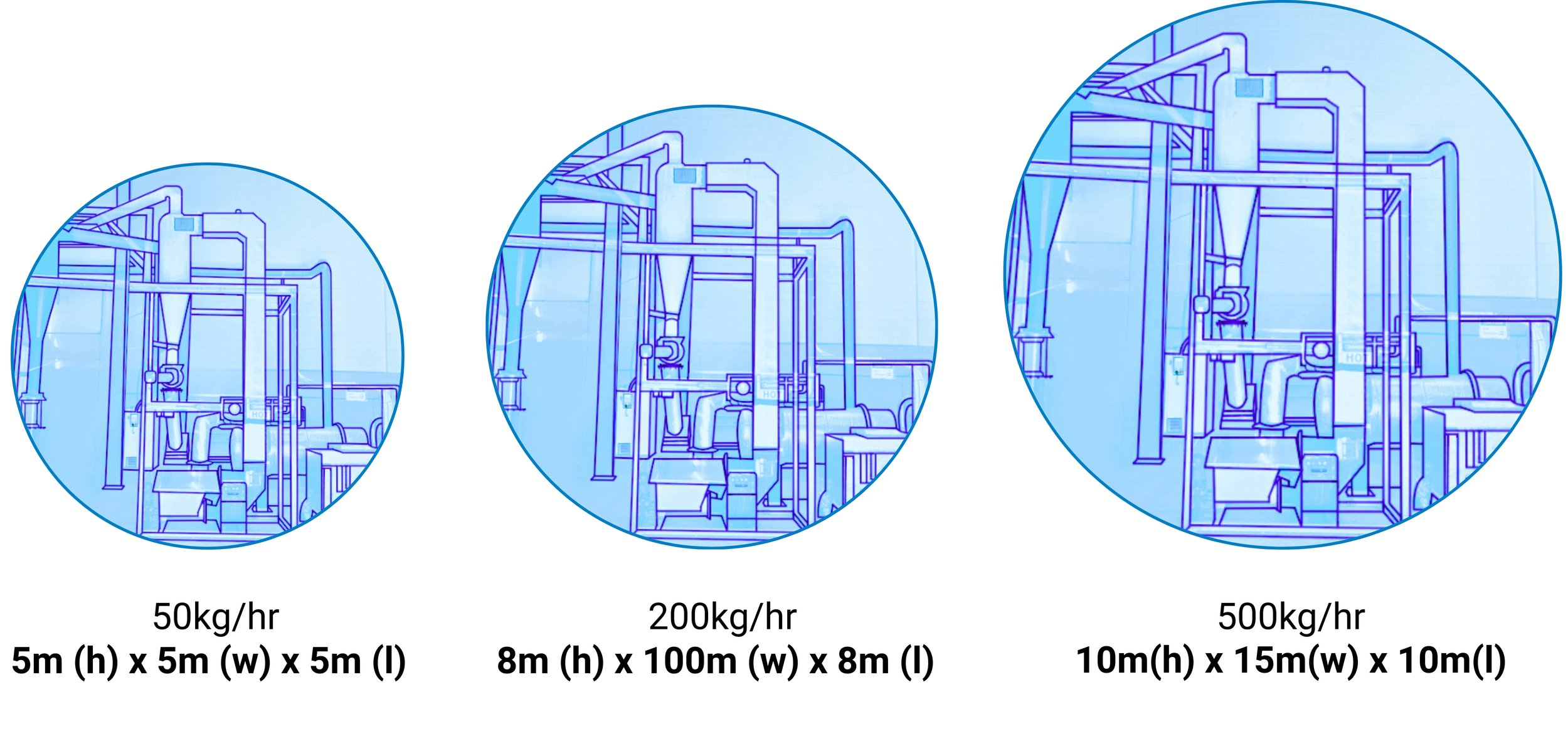

Industrial versions available in different throughput capacities from 50kg/hr all the way to 500kg/hr with minimal increase in footprints.

* Estimated footprint only-Depends on site conditions and feedstock characteristics

Questions you should be asking before you invest in other dryers

Can it generate powders affordably and quickly?

Can it process both solid and liquid feedstocks simultaneously?

Can it reduce drying costs to less than 50% of today’s industrial norms?

Can it fit under 15m roof space?

Can it dry and mill at the same time?

If you said NO to any of these

Welcome to the gateway of the PX20 ecosystem

PX20 MPD now enables you to have access to these growing markets

All possible with PX20 MPD

This is the world which the PowderX20 MPD enables

We warmly invite you to join us in this exciting future.

A world where:

Farmers become manufacturers of fruit and vegetable powders

Animal processors go beyond meat and become producers of nutraceutical ingredients

Countries strengthen food security

Waste becomes value

Drying becomes opportunity

R&D Center:

Welcome to Brisbane Research and Innovation Campus.

Our Brisbane Campus exists for one purpose: to de-risk your investment decision and accelerate your innovation.

Inside our state-of-the-art facility, you will find:

A fully equipped pilot plant

Capability to test diverse solid and liquid feedstocks

Systems identical to full-scale PX20 units

Access to our technical experts at every step

Whether you are validating a material, optimising a recipe, or exploring new products, our facility lets you test before you invest.

Join us as we lead the change creating a future where drying is efficient, sustainable, and uncompromising on quality

Head Office

Level 14, 115 Pitt Street, Sydney NSW 2000

1300 302 946

Research & Innovation Campus

45 Argyle Parade, Darra, QLD 4076

0450 434 774